Megmeet Intelligent Digital Welding Machine

Megmeet Welder

Dibangun ing 2003

TOP 3 ing China

Profil Megmeet

MEGMEET

karyawan:

3200+

Teknisi R&D:

650+

100+

mitra

200+

Saka Huawei&Emerson

12+

Model Klasik

400+

Paten

8 Pusat R&D

2 Basis Produksi

Biaya sing luwih murah tegese bathi sing dhuwur

- Nyimpen kanthi downtime sing luwih murah. Kanthi desain sing nglindhungi dhewe, sumber daya bakal nampilake kode kesalahan ing meter. Sawise kasalahan dibusak, sistem bakal bali menyang normal. Breakdowns lan downtimes bakal dicegah.

- Ngirit kanthi konsumsi daya sing luwih murah. Konsumsi daya 7 KWH disimpen sawise welding saben spoll kabel MIG, dibandhingake karo mesin welding thyristor (SCR).

- Nyimpen kanthi kemampuan kanggo ketemu macem-macem kekandelan. Kanggo saiki output beda, kinerja welding wis maintained ing tingkat marem.

- Nyimpen kanthi nganyari piranti lunak spesifikasi prosedur pengelasan. Sawise proses welding anyar dijaluk, pangguna pungkasan bisa nganyarke piranti lunak aplikasi welding tinimbang nandur modal menyang sistem welding sing anyar.

- Nyimpen liwat kontrol kualitas welding. Kanthi fungsi ngunci-up, Managers QC ing situs bisa kanggo nyegah owah-owahan rasah saka specification welding dening welders. Biaya inspeksi bakal disimpen akeh.

- Simpen liwat sistem kontrol grup. SMARC, sistem kontrol klompok, bisa kanggo link sumber daya welding saka jumlah gedhe kanggo MES. Biaya manajemen bakal disimpen kanthi akeh liwat ngawasi spesifikasi pengelasan, liwat ngumpulake lan nganalisa data.

Spesifikasi

| Manual | Eve CM 500 H | Entuk CM 500 | Entuk CM 400 | Entuk CM 350 | Entuk CM 250 |

| Robotika | Ehave CM 500 H AR | Ehave CM 500 AR | Ehave CM 400 AR | Ehave CM 350 AR | Ehave CM 250 AR |

| Mode Kontrol | Full Digital-Control | ||||

| Input RatedTegangan | AC 3PH 380V +/-25% (3PH 250V ~ 3PH 475V) | ||||

| Frekuensi Input | 30 ~ 80 HZ | ||||

| Dirating Daya Input | 24 KVA | 22.3 KVA | 16,8 KVA | 13,5 KVA | 8 kva |

| Faktor Daya | 0.93 | 0.93 | 0.94 | 0.94 | 0.94 |

| Efisiensi | 86% | ||||

| Dirating OCV | 75 V | 73.3V | 63.7V | 63.7V | 63.7V |

| Dirating Output Saiki | 30~500A | 30~500A | 30~400A | 30~400A | 30~400A |

| Tegangan Output Rated | 12 ~ 45V | 12 ~ 45V | 12 ~ 38V | 12 ~ 38V | 12 ~ 38V |

| Siklus tugas | 500A 100% @ 40°C | 500A 60% @40°C390A 100% @40°C | 400A 60% @40°C310A 100% @40°C | 350A 60% @40°C271A 100% @40°C | 250A 100% @40°C190A 100% @40°C |

| Materi sing ditrapake | Baja Karbon | ||||

| WeldingProses | CO2 / MAG / FCAW / MMA | ||||

| Diameter kawat | φ1.0/1.2/1.6 mm | φ0.8/1.0/1.2 mm | |||

| WeldingOperasiMode | 2T / 4T / bola-bali 4T / Spot Welding | ||||

| ParamèterSaluran | 10 (Standar) | ||||

| Lingkup Induktansi (Busur Lembut/Kuat) | -9~ +9 | ||||

| Komunikasikaro RobotPengontrol | Analog | ||||

| dilindhungiKomunikasiAntarmuka | BISA | ||||

| Mode pendinginan | Cerdas Air Cool | ||||

| Pakan kawatKacepetan | 1,4 ~ 24 m/min | ||||

| elektromagnetikKompatibilitas | IEC60974:10 EMS | ||||

| Isolasisasmita | H | ||||

| Ingresspangayoman | IP23S | ||||

| pangayomannglawanLightening | Kelas D (6000V/3000A) | ||||

| nyambut gaweSuhu &Kelembapan | -39°C~ +50°C; Kelembapan ≤ 95%; | ||||

| Ukuran (L/W/H) | 620x300x480 mm | ||||

| Bobot reged | 52 Kg | 52 Kg | 48 Kg | 48 Kg | 48 Kg |

| Manual | Artsen Plus 500 D/P/Q | Artsen Plus 400 D/P/Q | Artsen Plus 350 D/P/Q |

| Robotika | Artsen Plus 500 D/P/QR | Artsen Plus 400 D/P/QR | Artsen Plus 350 D/P/QR |

| Mode Kontrol | Full Digital-Control | ||

| Dirating Tegangan Input | AC 3PH 380V +/-25% (3PH 250V ~ 3PH 475V) | AC3PH 380V +/-25%(3PH 250V ~ 3PH 475V)AC 3PH 220V +/-15%(3PH 187V ~ 3PH 254V) | |

| Frekuensi Input | 45 ~ 65 HZ | ||

| Dirating Daya Input | 24 KVA | 22.3 KVA | 16,8 KVA |

| Faktor Daya | 0.93 | ||

| Efisiensi | 87% | ||

| Dirating OCV | 85 V | ||

| Dirating Output Saiki | 30 ~ 500 A | 30 ~ 500 A | 30 ~ 400 A |

| Tegangan Output Rated | 12 ~ 45 V (Presisi ing 0.1V) | ||

| Siklus tugas | 500A / 39V 60% @ 40°C387A/ 33.5V 100% @ 40°C | 400A / 34V 100% @ 40°C | 350A / 33.5V 60% @ 40°C270A / 27.5V 100% @ 40°C |

| Materi sing ditrapake | D: Baja Karbon/Stainless SteelP: Baja Karbon / Baja Tahan KaratQ: Baja Karbon/Stainless Steel/Aluminium Ally | ||

| Proses Welding | D: MIG / MAG / CO2; Low- spatter;D: MIG / MAG / CO2; Low-spatter; Short-arc PulseQ: MIG / MAG / CO2; Low-spatter; Short-arc Pulse | ||

| Diameter kawat | φ0.8/0.9/1.0/1.2/1.6 mm | ||

| Mode Operasi Welding | 2T / 4T / Khusus 4T / Spot Welding / Leaping Welding | ||

| Lingkup Induktansi (Busur Lembut/Kuat) | -7~ +7 | ||

| Fungsi Obor Push-pull(1) | ya wis | ||

| Komunikasi karo Robot Controller | Analog; DeviceNet; BISA mbukak; MEGMEET BISA; EtherNet/IP (2) | ||

| Digital Meter ing Wire-feeder | ya wis | ||

| Mode pendinginan | Udara Kelangan; Banyu Kelangan (Opsional) | ||

| Kompatibilitas elektromagnetik | IEC60974:10 EMS | ||

| Kelas Isolasi | H | ||

| Ingress Protection | IP 23S | ||

| Perlindhungan marang Lightening | Kelas D (6000V/3000A) | ||

| Suhu Kerja & Kelembapan | -39°C ~ +50°C; Kelembapan≤95%; | ||

| Ukuran (L/W/H) | 620x300x480 mm | ||

| Bobot reged | 52 Kg | ||

| Manual | Artsen PM 500 F/N/AS/AD ll | Artsen CM 500 ll | Artsen PM 400 F/N/AS/AD ll | Artsen CM 400 ll |

| Robotika | Artsen PM 500 F/N/AS/AD R ll | Artsen CM 500 R ll | Artsen PM 400 F/N/AS/AD R ll | Artsen CM 400 R ll |

| Mode Kontrol | Full Digital-Control | |||

| Dirating Tegangan Input | AC 3PH 380V +/-25% (3PH 250V ~ 3PH 475V) | |||

| Frekuensi Input | 30 ~ 80 HZ | |||

| Dirating Daya Input | 24 KVA | 22.3 KVA | 19.7 KVA / 18KW | 15 KVA / 12.7KW |

| Faktor Daya | 0.93 | |||

| Efisiensi | 87% | |||

| Dirating OCV | 73.3 V | |||

| Dirating Output Saiki | 30 ~ 500 A | 30 ~ 500 A | 30 ~ 400 A | 30 ~ 400 A |

| Tegangan Output Rated | 12~45 V (Presisi ing 0.1V) | |||

| Siklus tugas | 500A 60% @ 40°C390A 100% @ 40°C | 500A 60% @ 40°C390A 100% @ 40°C | 400A 100% @ 40°C | 400A 100% @ 40°C |

| Materi sing ditrapake | F: Baja KarbonN: Baja Karbon / Baja Tahan KaratAS/AD: Baja Karbon /Stainless Steel/Aluminium Alloy | Baja Karbon | F: Baja KarbonN: Baja Karbon / Baja Tahan KaratAS/AD: Baja Karbon /Stainless Steel/Aluminium Alloy | Baja Karbon |

| Proses Welding | VMIG/MAG/CO2Pulse MIG/MAGDobel Pulse MIG / MAG | MIG / MAG / CO2 | MIG/MAG/CO2Pulse MIG/MAGDobel Pulse MIG / MAG | MIG / MAG / CO2 |

| Diameter kawat | φ0.8/1.0/1.2/1.6 mm | φ0.8/1.0/1.2 mm | ||

| Mode Operasi Welding | 2T / 4T / Khusus 4T / Spot Welding | |||

| Parameter Saluran | 50 (Standar) | |||

| Lingkup Induktansi (Busur Lembut/Kuat) | -9~ +9 | |||

| Fungsi Obor Push-pull(1) | ya wis | |||

| Komunikasi karo Robot Controller | Analog; DeviceNet; BISA mbukak; MEGMEET BISA; EtherNetIP (2) | |||

| Digital Meter ing Wire-feeder | ya wis | |||

| Mode pendinginan | Udara Kelangan; Banyu Kelangan (Opsional) | |||

| Kompatibilitas elektromagnetik | IEC60974:10 EMS | |||

| Kelas Isolasi | H | |||

| Ingress Protection | IP 23S | |||

| Perlindhungan marang Lightening | Kelas D (6000V/3000A) | |||

| Suhu Kerja & Kelembapan | -39°C ~ +50C; Kelembapan ≤ 95%; | |||

| Ukuran (L/W/H) | 620x300x480mm | |||

| Bobot reged | 52KG | |||

| Artsen CM 500C | |

| Mode Kontrol | Full Digital-Control |

| Komunikasi Carrier-Wave | Komunikasi gelombang Pembawa Digital Kacepetan dhuwur |

| Dirating Tegangan Input | AC 3PH 380V +/-25% (3PH 250V ~ 3PH 475V) |

| Frekuensi Input | 30 ~ 80 HZ |

| Dirating Daya Input | 24 KVA |

| Faktor Daya | 0.93 |

| Efisiensi | 86% |

| Dirating OCV | 75V |

| Dirating Output Saiki | 50~500 A |

| Tegangan Output Rated | 12 ~ 50 V (Presisi ing 0.1V) |

| Siklus tugas | 500A / 39V 100% @ 40°C |

| Materi sing ditrapake | Baja Karbon |

| Proses Welding | CO2/MAG/FCAW/MMA |

| Diameter kawat | φ1.0/1.2/1.4/1.6 mm |

| Mode Operasi Welding | 2T / 4T / Khusus 4T |

| Parameter Saluran | 10 (Standar) |

| Lingkup Induktansi (Busur Lembut/Kuat) | -9~ +9 |

| Antarmuka Komunikasi Reserved | BISA |

| Mode pendinginan | Adem hawane |

| Digital Meter ing Wire- feeder | YA |

| Wire-dipakani Speed | 1,4 ~ 24 m / min |

| Kompatibilitas elektromagnetik | IEC60974:10 EMS |

| Ingress Protection | IP 23S |

| Kelas Isolasi | H |

| Perlindhungan marang Lightening | Kelas D (6000V/3000A) |

| Suhu Kerja | -39°C~ +50°C |

| Ukuran (L/W/H) | 620x300x480mm |

| Bobot reged | 52 Kg |

| Manual | Dex DM 3000 | Dex DM 3000 S | Dex PM 3000 | Dex PM 3000 S Kab |

| Robotika | - | Dex DM 3000 R | - | Dex PM 3000 R |

| Mode Kontrol | Full Digital-Control | |||

| Dirating Tegangan Input | AC 3PH 380V -15%~ +21% (3PH 323V ~ 3PH 460V) | |||

| Frekuensi Input | 45 ~ 65 HZ | |||

| Dirating Daya Input | 9,2 KVA / 8,7 KW | |||

| Faktor Daya | 0.94 | |||

| Efisiensi | 81% (210A/ 24.5V | |||

| Dirating OCV | 54.2 V | |||

| Dirating Output Saiki | 280 A | |||

| Output Range Saiki | 30A~ 300A | |||

| Tegangan Output Rated | 12 ~ 30 V (Presisi ing 0.1V) | |||

| Siklus tugas | 280A/ 28V 60% @ 40°C 217A / 24.9V 100% @ 40°C | |||

| Materi sing ditrapake | Baja Karbon/Stainless Steel | Baja Karbon / Baja Tahan Karat / Paduan Aluminium | ||

| Proses Welding | MIG/MAG/CO2/MMA | MIG/MAG/CO2/MMA Pulsa MIG/MAG Dobel Pulse MIG/MAG | ||

| Diameter kawat | 0,8 / 0,9 / 1,0 / 1,2 mm | |||

| Mode Operasi Welding | 2T | 2T / 4T / Khusus 4T | ||

| Parameter Saluran | 50 (Standar)

| |||

| Lingkup Induktansi (Busur Lembut/Kuat) | -9~ +9 | |||

| Komunikasi karo Robot Controller | - | Analog; DeviceNet; BISA mbukak; MEGMEET BISA; EtherNet/IP

| - | Analog; DeviceNet; BISA mbukak; MEGMEET BISA; EtherNet/IP

|

| Digital Meter ing Wire-feeder | - | ya wis | - | ya wis Jinis terlampir karo digital meter (A/V) |

| Mode pendinginan | Udara Kelangan; Banyu Kelangan (Opsional) | |||

| Wire-dipakani Speed | 1,4 ~ 28 m/min | |||

| Kompatibilitas elektromagnetik | IEC60974:10 EMS | |||

| Kelas Isolasi | H | |||

| Ingress Protection | IP 23S | |||

| Perlindhungan marang Lightening | Kelas D (6000V/3000A) | |||

| Suhu Kerja & Kelembapan | -40°C ~ +70°C ; Kelembapan≤95%; | |||

| Ukuran (L/W/H) | 610x260x398mm | |||

| Bobot reged | 25,4 KG | 23,7 Kg | 25,4 KG | 23,7 Kg |

Desain pangguna-loropaken: trep kanggo nggunakake

Desain sing gampang digunakake kanggo tukang las sing ora duwe katrampilan

- Fungsi Built-in Anti-shake

- On / Off Pilihan saka Synergi Control

- On / Off Opsi Penetrasi Konstan

Fungsi Locking

- Tanpa piranti eksternal, sandhi ngunci bisa disetel ing panel ngarep. Spesifikasi welding sing dijaluk bakal dicegah saka owah-owahan sing ora perlu. Biaya manajemen lan inspeksi bakal diturunake, dene kualitas welding bakal dijamin.

Recovery cepet saka Produksi

- Struktur sing dipasang lan desain modular nambah linuwih. Dismantling lan re-assembly bakal cendhak ing konsumsi wektu.

- Sumber daya dirancang kanggo ndeteksi kelainan ing kabeh sistem. Kode kesalahan bakal ditampilake, nanging sumber daya ora bakal rusak.

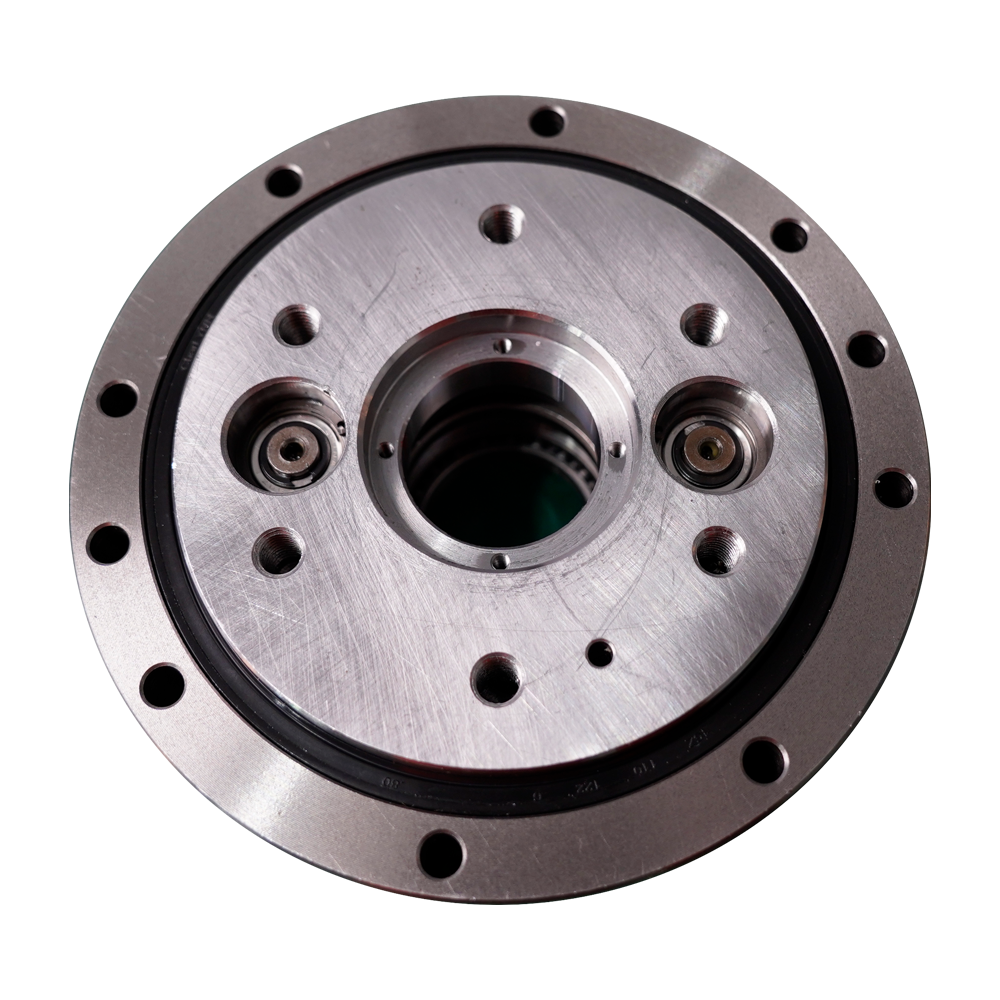

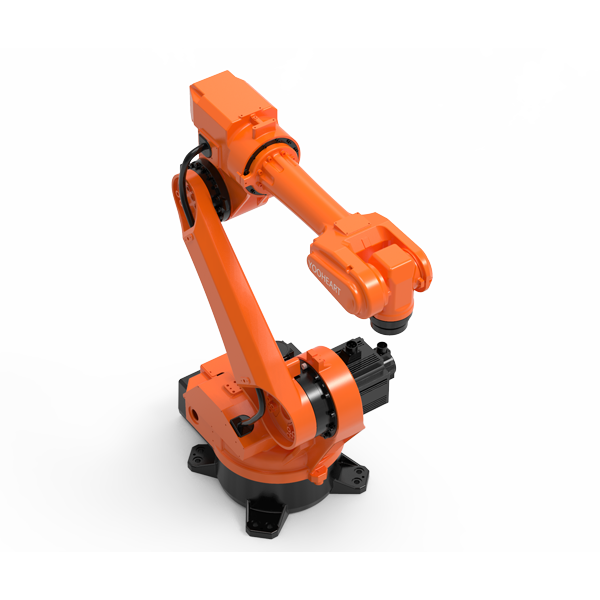

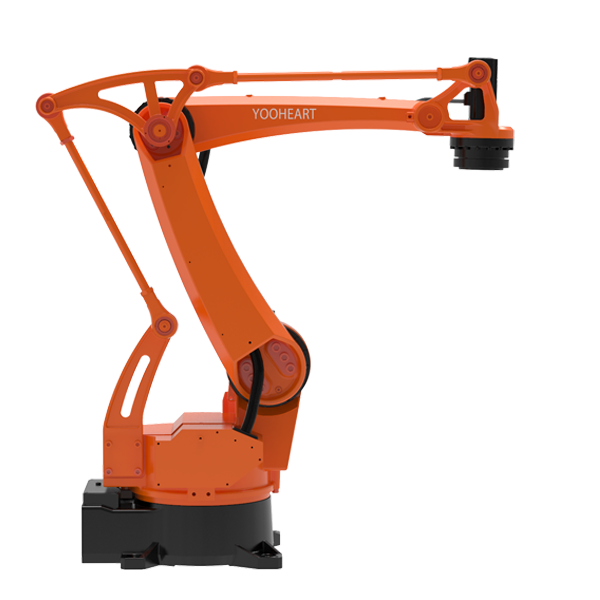

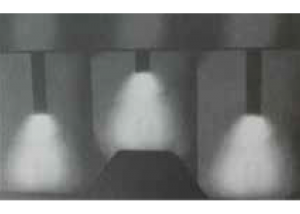

Aplikasi Robotic Welder

Robot Honyen Kanthi mesin las Megmeet

Robot Yooheart kanthi sumber daya las digital Megmeet

Megmeet Pelanggan